About a month ago, Christopher Bartocci of Small Arms Solutions, posted on his website an AR-15 rifle that he was going to sell (already sold out). When I visited the page, I was really intrigued by the description of the rifle. Chris wrote: “It has hand selected components to make a reliable combat rifle. This build is what I consider a combat reliable, well balanced, accurate and durable battle rifle.“. I was curious, what is THE build that the renown AR-15 expert considers the best? I immediately contacted Chris to find out the details concerning this build.

Before we proceed with the examination of this rifle, let me briefly tell you who is Christopher Bartocci and why I consider his opinion so valuable. Many of you probably know him, but for those of you who haven’t heard about this man, I’ll tell you about the most significant parts of his career. Chris is a former forensic firearms examiner. He worked for Colt, Otis Technology and LMT, has traveled all around the world training military and law enforcement personnel of different countries. He is the author of “Black Rifle II: The M16 Into the 21st Century” book and a number of articles in various publications. Chris is also the founder of Small Arms Solutions LLC.

As you can see, if there are people in the industry who can be called AR-15 gurus, then Chris is definitely one of them. He kindly answered all my questions and provided all the necessary information to study the subject and write this article.

The story of this build starts back in 2015 when Chris wrote a two-part article in Small Arms Review journal titled “Boutique Black Rifles”. In these articles, Bartocci wrote about four AR-15 builds that he considered the best ones of the time. The main idea behind these builds is to use the commercially available components that have characteristics far exceeding the military specifications which eventually result in extremely reliable AR-15 builds. The rifle that we are taking a look at today is the evolution of the number two rifle from the mentioned articles. Some of the components of this updated build were changed with newly introduced and more advanced ones compared to what was available in 2015.

Now let’s go through the key components that this rifle is made of and see what unique features of these parts made them to the list of Chris Bartocci’s combat-reliable AR-15 build parts.

San Tan Tactical Billet Upper and Lower Receivers

The San Tac Tactical SST-15 receivers are machined out of billet 7075 aluminum. The lower receiver features ambidextrous magazine release and bolt catch. It also has a couple of built-in QD sling swivel sockets located on either side, behind the takedown pin area. The magazine well is beveled to aid the magazine insertion process.

If you read the mentioned Small Arms Review articles, you’ll see that the first version of #2 Boutique Black Rifle was built with an Aero Precision upper receiver. Back in 2015 when Chris was building this rifle, San Tan Tactical didn’t have an upper receiver yet. So the upper is one of the parts that was changed compared to the first iteration of this build.

The bolt of this BCG is machined out 9310 steel and it’s magnetic particle inspected (MPI). The latter is a feature that Bartocci recommends to look for. The bolt, bolt carrier, extractor, gas key, and cam pin are chrome plated.

The design of this ambidextrous charging handle removes the stresses from the latch pin preventing it from breaking. Some other critical areas are beefed up compared to the mil-spec charging handle.

Chris Bartocci recommends this stock and receiver extension combination for several reasons. First of all, he considers the materials of the stock to be some of the most robust ones in the market. There are markings of stock positions on top of the buffer tube and the stock itself has a corresponding hole that shows the selected position of the stock. There are also battery compartments on either side of this stock.

Although the Vltor stock assembly comes with a buffer and recoil spring, Bartocci recommends using the JP Enterprises Silent Captured recoil spring assembly which proved to perform flawlessly removing the noise of the original spring and making the cycling of the action smoother.

This ambidextrous safety selector has a configurable design allowing to choose the size of the selector lever on each side of the gun. Bartocci prefers using the full sized lever on the left side of the gun and smaller size lever on the right side. The opposite layout would be correct for left-handed shooters. Such configuration will allow you to have safety selector levers on both sides of the gun with the secondary lever being small enough not to dig into your trigger finger.

This part is made of heat treated steel. The levers are textured to provide better purchase. They also have larger surface areas which make it easier to manipulate the safety with gloved hands.

Chris points out several important features of these takedown/pivot pins. Despite having virtually the same pinhead dimensions as the standard ones, the BAD EPS pins have an improved head design which makes pulling them out a much easier process. The pin tips also have a concave profile and slightly protrude from the left side of the receiver making pushing them out from left side easier both when pushing by hand or using a punch or a bullet tip.

Probably there is no need to introduce this pistol grip because it is well known among the firearm enthusiasts. Two main features of this grip are the interchangeable back and front straps and the compartment inside the grip where you can store an oil bottle, spare bolt and firing pin or batteries.

These triggers utilize a pair of coil springs which along with other design solutions provide a light trigger pull without compromising the sear engagement surface or the hammer strike energy. In fact, the hammers of these trigger assemblies strike with an increased energy compared to the mil-spec ones.

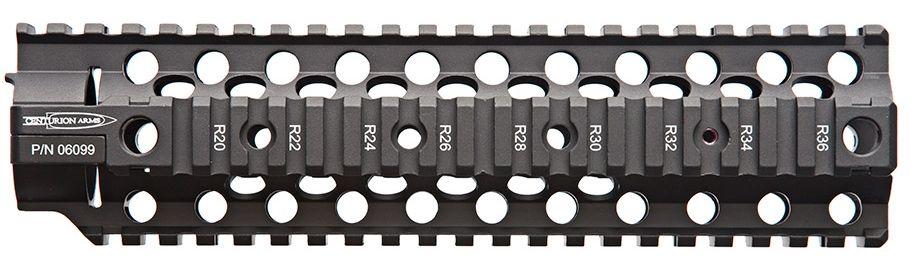

This free-floated quad rail is machined out of 6061 T6 aluminum and has a Type 3 hard coat anodized finish. It is installed onto the AR-15 pattern rifles by being clamped to standard barrel nuts. The installation does not require a removal of the front sight post.

In this build, Chris uses the FN cold hammer forged barrels. In general, he considers the cold hammer forging to be the best way of manufacturing barrels for combat firearms. Another feature that Bartoccci points out is the mid-length gas system which he considers an optimal one for the 16″ barrel. Last but not least, these barrels feature chrome lined bores and chambers.

The front sight of this A.R.M.S. product comes as a combination with the gas block. The front sight itself is a folding one and when deployed it forms the same shape as the standard M16/M4 gas block/FSB. According to Chris, the pinned gas block is an absolute must for a combat-reliable build ensuring that the gas block won’t come loose, rotate or slide forward.

The folding backup rear sight of this build is also made by A.R.M.S. Inc. It has several options of the aperture size and also a version with a notch on top of the aperture The windage is click-adjustable in .75 MOA increments.

According to Chris, this flash hider has proved to work perfectly. It reliably mitigates the signature of the rifle and does not compromise the shooter’s position.

And that’s the list of the key components used in the combat-reliable AR-15 build recommended by Christopher Bartocci. Let us know in the comments section what do you think about this build? What would you add or remove and why?

Images from: https://ift.tt/1l2zy5m, www.brownells.com, www.santantactical.com, https://ift.tt/1jPNQpu, www.magpul.com, www.centurionarms.com

via The Firearm Blog

Christopher Bartocci’s Combat-Reliable AR-15 Build