https://2.img-dpreview.com/files/p/E~C213x0S3413x2560T1200x900~articles/5410838737/20230228-DSC01945_-_shipping_and_receiving.jpeg

Introduction

If you’ve ever bought a new lens, you know the joy of removing a beautiful, pristine optic from its box and attaching it to your camera for the first time. But have you ever wondered what it takes to design and build that lens? During a recent trip to Japan, we had the opportunity to go behind the scenes at Sigma’s lens factory in the city of Aizu to answer that question, and we’re going to walk you through how it’s done, step by step.

Most photographers are familiar with Sigma, but maybe not with its unique history. Sigma is a family-owned business founded in 1961 by Michihiro Yamaki. Mr. Yamaki was an engineer at a small optical company that made binoculars, cameras and video lenses. When the company went bankrupt, some of its suppliers, needing new clients, approached Mr. Yamaki about starting a new business, and Sigma was born.

Today, Sigma has over 1,700 employees, nine subsidiaries in eight countries, and annual sales of 42 billion yen (about $322 million).

Sigma’s business today

As Sigma’s current CEO, Kazuto Yamaki, explained in our recent interview, Sigma has a business philosophy of ‘small office, big factory.’ It has a minimal administrative, sales and marketing staff and prioritizes investment in engineering and manufacturing. This explains why about 75% of the employees at the company’s headquarters in Kawasaki, Japan, are engineers.

Sigma opened its current factory in Aizu, about 300km north of Tokyo in Fukushima Prefecture, in 1974 and it’s home to about 1,500 of Sigma’s employees – the majority of its workforce. The proximity means that Sigma teams can quickly meet in person to resolve problems when needed to solve engineering and manufacturing challenges. This is Sigma’s only factory, and all of its products are made here.

Above: Sigma’s factory in Aizu, Japan.

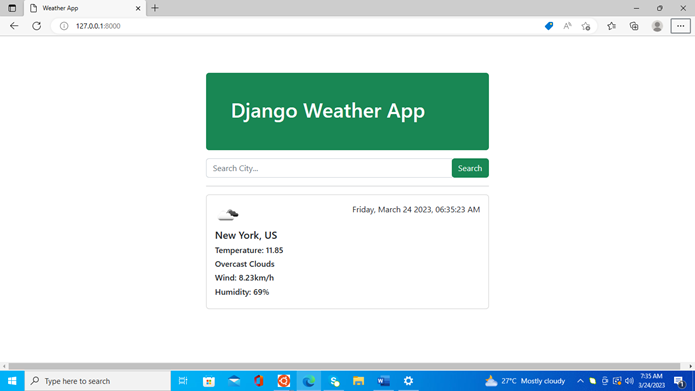

Sigma’s Aizu factory

Sigma’s factory covers almost 72,000 square meters of floor space (approximately 775,000 square feet) and produces 80,000 lenses and 2,000 cameras annually. It’s a vertically integrated factory, meaning that almost every aspect of manufacturing, including the individual parts that make up each lens – right down to the screws – are produced here.

From the company’s early days, Michihiro Yamaki believed that to make a good product, working with local people and businesses was essential. That approach continues to this day; all of Sigma’s suppliers are located in the northern part of Japan. Essentially, Sigma aims to do everything by itself and with local partners, an approach that paid off during the global pandemic. Unlike companies with complex global supply chains, Sigma was able to keep its factory in operation during that time.

With that background, let’s dive into how lenses are made.

Above: The Sigma’s Aizu factory in 1974 and today, with Mt. Bandai behind. (Image courtesy of Sigma)

Lens testing room

Since optics are the core of any lens, we’ll start with glass. Before diving into the manufacturing process, let’s talk about how Sigma establishes performance metrics for every lens it manufactures.

Each time a new lens is designed, a high-quality master copy is created which is used for benchmark testing; it establishes a baseline performance spec for each new interaction constructed. This baseline becomes the reference point for all Modulation Transfer Function (MTF) machines used throughout the lens manufacturing process, ensuring that each lens meets the design specification for resolution. Sigma designs and builds its own MTF machines in-house.

Testing of the master lens takes place on a Trioptic measurement machine, one of only a few of its type in Japan. It can measure the range between the minimum focusing distance and infinity for all of Sigma’s lenses and uses collimators up to 1000mm.

Glass: lens blanks

Most lens elements start as lens blanks, glass disks with a slight curve. Before any grinding occurs, lens blanks have an opaque, white appearance. Sigma uses lens blanks from Hoya to manufacture its lenses.

Glass grinding

The first step in the lens manufacturing process is to roughly grind out the curve of the lens. Each lens blank is attached to a plunger that guides it into a machine where the glass is ground to the correct curve for the lens. Since this part of the process is intended only to create the right shape for the lens, it still appears somewhat opaque when finished.

A second, more refined precision grinding step is then performed, which gives the lens its clear, smooth finish.

There are about 330 machines used in the glass manufacturing process at Sigma’s Aizu factory, and every few minutes a technician is checking one with a gauge to ensure that its curve is correct.

Lens polishing

After the lenses are ground, the third and final step is polishing. Lenses are set into a machine on polyurethane pads mounted in a mold that matches the final shape or curve of the lens. These grind the lens using a special polishing paste, typically cerium or zirconium oxide. The process usually takes two to ten minutes, depending on the size and type of the lens.

Glass molding

Not all glass elements are ground. Aspherical optics are manufactured through glass molding using one of two processes, depending on their size. Smaller elements begin life as what looks like a bulbous glob of clear optical glass, while larger elements begin as pre-formed glass units.

In both cases, these pieces of glass are put into molds and pushed through a machine that presses them into their final shape using high pressure and heat. Sigma currently manufactures aspherical elements up to 84mm in diameter. Sigma also makes its own molds for manufacturing aspherical lenses, part of its philosophy of building its own tools in-house to maintain quality control.

Aspherical lens manufacturing is one of the better-guarded parts of the lens manufacturing process and something that makes lenses unique, so we were asked to refrain from taking photos in this area. Instead, I’ve included a picture above of one of my favorite Sigma lenses, the 14mm F1.8 Art, which features a front aspherical element that’s 80mm in diameter.

Lens centering

After glass elements are formed and coated, they receive a final grinding around the edges to make sure the diameter and thickness of the edges of the elements are within specifications and will mount correctly inside the lens. This also ensures that the glass elements will be optically centered inside the lens housing.

Lens coatings

Once lenses are polished or molded, it’s time to apply Sigma’s Super Multi-Layer coatings, which suppress flare and ghosting. Before applying coatings, each lens is visually inspected for dust. The lens is then loaded onto a ‘planet,’ a dome-shaped device with inserts for specific lens elements.

The planets are then loaded into machines in which special chemicals have been evaporated into a chamber. The planet rotates inside the device, evenly spreading the vaporized chemicals onto the lens elements, before holding them to be cured by UV light.

Lens caulking, joining and bonding

Once the individual optical elements are manufactured, those that get grouped in a lens go through a process called caulking and joining. Each element is placed into a plastic frame, and high heat and pressure are used to fix them into place, creating a single unit made of multiple lens elements.

A separate process called lens bonding (photo above) is used when two to three elements must be bonded directly with no space in between. The two lenses are joined with a special adhesive, and a machine ensures that both lenses are optically centered. The bonded lenses are then exposed to UV light to cure the adhesive.

Metal processing

Now that we’ve covered glass, let’s move on to the rest of the manufacturing process, starting with metals. A lens has many metal parts, so metal processing covers a large part of the factory floor, producing components out of materials like steel, aluminum and brass.

The automated blue machines visible in the photo above carry out the process of cutting out, shaping and drilling holes in metal for a perfect fit. The process is quick, often taking only a few minutes per part. The factory runs about 160 of the machines you see in the photo.

Metal processing

Although numerous parts are produced in this factory area, lens barrels and bayonet mounts are the most recognizable. This photo shows freshly milled inner rotation barrels for lenses before any surface treatment has been applied.

Recycling

The machining process that turns metal blocks into lens components produces metal waste, like the shavings in this photo. Sigma captures this material and works with a local recycling facility to ensure the materials are repurposed rather than landing in a landfill.

Metal pressing

Some metal parts are stamped out by machines rather than being machined individually. In this case, a strip of metal is fed through a pressing machine by what looks like a giant roll of metal tape.

Metal pressing

And here’s the final product you saw being stamped out on the previous page: metal plates that help control the movement of the aperture blades on a lens.

Magnesium processing

For safety reasons, magnesium parts are machined in a separate building that isn’t connected to the main factory. Magnesium can be flammable, mainly when it’s in a fine shaving or powder form – precisely the forms you tend to produce when milling parts out of metal. As a result, this facility has extra thick concrete walls that offer protection in the event of an accident.

Magnesium is used for many components because it’s strong and durable yet lighter than aluminum. This allows parts to be smaller and lighter than if they were made from aluminum, but there’s a tradeoff: magnesium is more costly. As a result, it’s not used for everything, but only for parts where durability and light weight matter.

Magnesium components start as die-cast parts, one of the few items Sigma doesn’t produce in its factory. There are only a small number of suppliers for die-cast parts worldwide, and Sigma only sources die-cast from a limited number of suppliers in Japan. This photo shows a die-cast lens collar on the left and a fully machined version on the right.

Magnesium machining

These automated machines cut out, shape and drill holes in the die-cast part with high precision. After milling, each piece goes through a cleaning process to remove oils left over from production, then receives a corrosion-resistant coating to protect the metal. Once milling is complete, each part is measured by a machine to make sure it’s within the specified tolerances for the part. In this photo, you can see a tripod collar mounted to a machine.

At any given time, there are about 20 machines milling parts from die-cast magnesium. For safety, each machine is equipped with specialized fire extinguishing equipment explicitly designed for magnesium fires.

New tool and mold creation

Sigma’s philosophy is to control as much of the manufacturing process as possible in its factory, as that allows them to better control the quality of everything it produces. This extends to the molds and tools used to manufacture its products.

This area isn’t automated. Prototypes and parts are handmade, as seen in the photo above. Hand-made parts become blanks and are used to create the injection molds used to manufacture many components. This is also where Sigma builds the specialized tools required to build a new product, typically with a focus on making the assembly process more efficient.

Injection molding

Molds for plastic or pressed parts are made using a process called electronic discharge machining (EDM). This thermal process removes material by applying discharging sparks in the gap between an electrode and the part being manufactured.

Once on the assembly line, viscous plastic is fed into the mold through the center of the mold. A separate series of tubes delivers coolant to the mold, causing the plastic parts to harden. Around 40 injection molding machines are making parts on the assembly line at any given time, and molds will be rotated in and out of production depending on what products are being produced.

Surface mounting

Surface mounting refers to mounting electronics onto circuit boards for lenses. As with many things, Sigma manufactures circuit boards in-house. Baseboards are fed into one end of a machine where soldering paste is applied and heated to spread out the paste evenly. Components are then fed into the machine from rolls that look like tape and stamped onto the board.

Surface mounting

A 3D photo test of each board confirms that all the parts are in the correct positions, followed by an X-ray check. There are about 20 machines in the factory building circuit boards.

The board in this photo is a two-sided circuit board. One side has been printed and is now ready to feed back through the machine for surface mounting on the opposite side.

Painting, printing and surface treatment

Once metal parts like lens barrels have been milled, and any necessary surface coatings applied, it’s time for a paint job. Each part is mounted on a metal jig which spins in circles as the paint is sprayed on, ensuring an even coat of paint. These painted parts are then dried in ovens.

Some materials, like those made of aluminum, may receive a black anodized coating instead.

Printing

Most of the reference markings on a lens, like scale windows and apertures, as well as labels on accessories like lens hoods, are printed or painted on. A technician applies the ‘Sigma’ logo to part of a lens barrel in this photo.

Electroplating

Electroplating is used to apply a chrome surface to metal parts, which makes them more durable. The most recognizable parts to go through the electroplating process are the brass lens mounts for each lens, which are chrome-plated here. Some smaller metal parts are plated here as well.

Final assembly and quality assurance

Once all lens elements are made and all parts have been manufactured, surface treated and painted, they meet at the final assembly line. In this clean room environment, each line is set up based on what models are in production on a given day. A single assembly line extends from the first set of parts to the final build.

Each lens’ alignment is performed using Sigma’s in-house designed and built MTF machines to adjust and confirm that they meet MTF specs. Although total assembly time varies by product, it can take as little as 30 minutes to assemble one lens, but it can certainly extend to longer periods for complex products.

After assembly, lenses are sent to the quality assurance division, which checks them using an MTF measuring machine. Additionally, they are inspected for dirt, surface scratches and other anomalies, and to confirm that zoom mechanisms, apertures and electronic contacts all work correctly. Some products may go through a resolution test at this stage as well.

Packing and shipping

Products arrive in the packing and shipping area without serial numbers. Until a product receives a serial number, it’s like a person without an identity. Once a serial number is assigned, the lens learns where it will be shipped.

Finished products and accessories are matched together and boxed in retail packaging, then loaded into large cardboard shipping boxes based on their final destination.

Finished product storage

The final step before a product leaves the factory is to be placed into the finished product storage area. With over 60 lens models in production across multiple lens mounts, there are a lot of lenses in this room. Products don’t sit here long – Sigma’s factory is producing at capacity, and there’s a constant need to clear this space to make room for new products coming off the assembly line.

Trucks arrive in the evening to ship boxes off to Narita airport in Tokyo, where they will be sent to distributors or subsidiaries worldwide.

I’m pretty sure the Ark of the Covenant is hiding in here somewhere.

Customer support and service

In addition to manufacturing, the Aizu factory serves as a center for Sigma’s customer support services. Most items received for repair here are from Japan (most countries will have their own service centers). However, products from other regions may be sent here if they require specialized repair.

Once a product is checked in, it’s handed over to one of Sigma’s ace repair technicians, who will repair it to Sigma’s original specifications, ensuring that it does so using the projection room shown on the next slide.

Projection room

The projection room, located next to the customer support and service area, is used to test products before and after repair. On the opposite side of the room, there’s a reverse projector for testing Sigma’s cinema lenses.

Sigma’s standard practice is to test lenses on both the resolution chart and MTF machine to ensure that they meet Sigma’s product specs before returning them to customers.

Additionally, technicians will even go outside to take real-world before and after photos to check a lens depending on the nature of the repair, for example to check for flare.

Sigma museum

Of course, no visit to Sigma would be complete without a trip to the Sigma museum, where it’s possible to see cameras and lenses past and present. There’s a lot to see, including modern lenses, classic lenses, SA-mount lenses and even cameras, like Sigma’s SD10 DSLR or compact Merrill models.

Finding some of the lenses you used early in your photography career is a fun, nostalgic trip down memory lane.

Articles: Digital Photography Review (dpreview.com)

Recommended:

Recommended: