https://www.ammoland.com/wp-content/uploads/2024/05/zbmlogihpsy-500×281.jpg

Building an AR-15 from scratch or enhancing an existing one can be a gratifying experience for any firearm enthusiast.

However, it’s a process that demands precision and awareness of common pitfalls. Steve and Caleb from Brownells delve deep into the crucial aspects of AR-15 assembly that can make or break your build. Avoid these mistakes on your next rifle build.

Key AR Rifle Builder Mistakes & How to Avoid Them

Mounting Accessories that Impact the Gas Block

One of the most common mistakes in AR-15 assembly is the incorrect mounting of accessories, such as bipods, that affect the gas block. This error can shift the barrel’s alignment subtly but significantly, compromising the rifle’s accuracy. To avoid this, it is crucial to select the attachment point carefully and use shorter screws if necessary to ensure that these do not exert undue pressure on the gas block.

Gas Block Alignment

Proper alignment of the gas block with the barrel’s gas port is essential for the reliable operation of your AR-15. Misalignment can result in cycling issues due to insufficient gas flow, leading to operational failures. When installing the gas block, ensure it is perfectly aligned with the gas port for optimal performance. This precise fit is crucial for maintaining the rifle’s reliability and longevity.

Over-Torquing the Castle Nut

While it might seem minor, applying too much torque to the castle nut can cause serious damage to the threads of the receiver extension or buffer tube. The recommended torque setting is 40 foot-pounds. Exceeding this can deform the buffer tube and other connected components, potentially leading to irreversible damage.

Excessive Material Removal in Upper Receiver Lapping

Lapping the upper receiver can be beneficial for ensuring a flush fit between the barrel and the receiver. However, removing too much material can result in the barrel sitting too far inside the upper receiver. This misplacement can affect feed ramp alignment and gas block positioning, which could lead to functional issues. Controlled lapping is necessary to achieve the right fit without compromising the structural alignment of the receiver.

Improper Buffer Tube Installation

The correct installation of the buffer retainer and spring is vital for the proper functioning of your AR-15. An incorrectly installed buffer tube can prevent the upper receiver from closing correctly, which could lead to operational failures. Ensuring that these components are installed at the proper depth is essential for their optimal performance.

Live Inventory Price Checker

|

Cmmg Ar-15 Parts Kit Hd Pivot & Takedown Pins |

Brownells.com |

$ 18.99 |

|

|

|

PSA AR15 Parts Replacement Kit |

Palmetto State Armory |

$ 12.99 |

|

|

PSA AR15 Parts Replacement Kit |

Palmetto State Armory |

$ 12.99 |

|

|

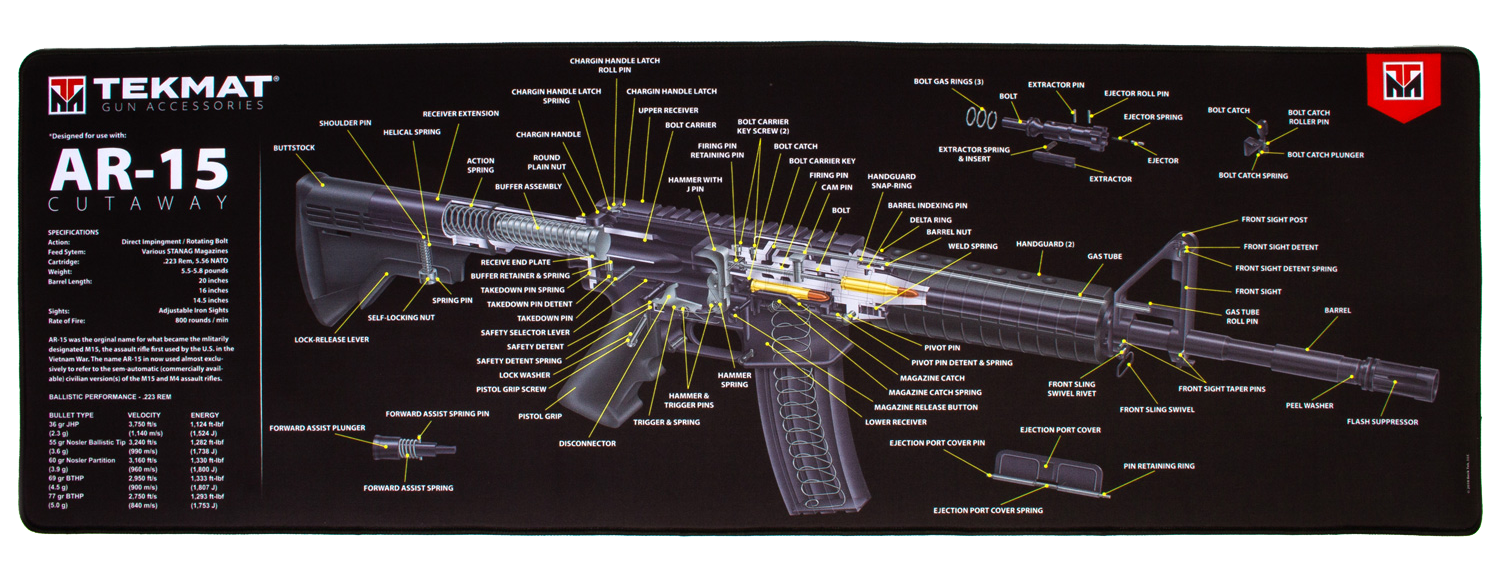

TekMat TEKR44AR15CA AR15 3D Cutaway Ultra 44 Cleaning Mat AR15 Parts Diagram 15 x 44 |

Ammunition Depot |

$ 21.99 |

|

Lock & Load

Building an AR-15 requires attention to detail and an understanding of the intricacies involved in its assembly. By avoiding these common mistakes, you can ensure the creation of a reliable and accurate firearm. Remember, every mistake is a learning opportunity. Share your experiences and tips within the AR-building community to help others avoid common pitfalls and enhance their building skills.

We encourage our readers to engage with the content, share their personal insights, and discuss their building experiences in the comments below. Whether you are a novice or a seasoned builder, there is always more to learn in the evolving world of firearm assembly.

AmmoLand Shooting Sports News