https://s3files.core77.com/blog/images/1778860_81_139479_DPvJRSCKT.jpg

Furnituremakers among you undoubtedly remember your most difficult glue-up: A countertop, bench or tabletop of unwieldy dimensions. Well, you probably won’t complain again, after seeing what these folks are doing. Swiss timber company Huesser Holzleimbau, which specializes in creating glue-lam beams, recently won a contract to manufacture two burly beams for a bridge.

Twenty-eight employees (including people from the office called onto the shop floor to pitch in) worked together on the most massive glue-up I’ve ever seen:

Once all of the separate glue-ups were put together, the resultant part was 27.3 m (90 ft) long, with a width and height of 1320 x 1360 mm (52 x 54 in). Counting the steel brackets embedded into the beam, it weighs 24.1 tonnes (53,130 lbs)! And they made two of them.

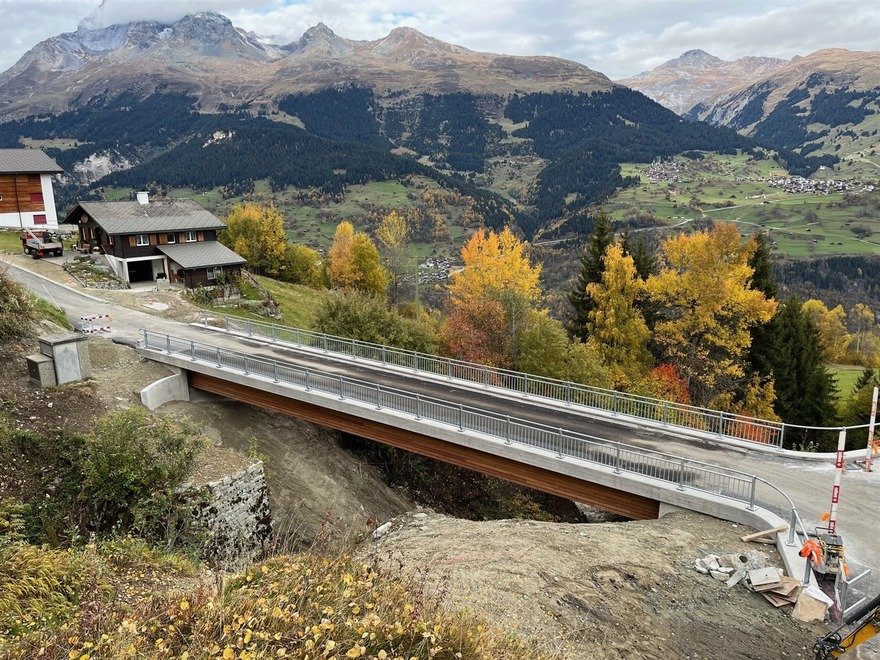

Located in Obersaxen, Switzerland, the Lochlitobel Bridge was erected last month to span a gorge.

As for why they made it out of wood and not steel, it was actually faster and required less logistics to make it out of wood. Glue-lam beams have 1.5 to 3 times the strength-to-weight ratio of steel, and could thus be fabricated offsite, trucked to the site and hoisted into place with less equipment than would have been required with heavy steel.

"During the entire construction period, no auxiliary bridges would have been possible, and there would have been virtually no convenient detour options," writes the Canton of Graubunden, where the bridge is located. "To minimize traffic restrictions, the two wooden load-bearing girders, each weighing 25 tons and over 27 meters long, were prefabricated and then installed on site with millimeter precision. This process ensured high quality and, from the dismantling of the old bridge to the commissioning of the new one, a road closure of only eight weeks."

Core77