https://substackcdn.com/image/fetch/w_1456,c_limit,f_auto,q_auto:good,fl_progressive:steep/https%3A%2F%2Fbucketeer-e05bbc84-baa3-437e-9518-adb32be77984.s3.amazonaws.com%2Fpublic%2Fimages%2F15a5cb1e-d849-441e-8865-998c6b2d283d_400x400.webp

Once a week we’ll send out a page from Cool Tools: A Catalog of Possibilities. The tools might be outdated or obsolete, but the possibilities they inspire are new. Sign up here to get Tools for Possibilities a week early in your inbox.

Flexible epoxy

This is as close to “bombproof” as I have found a glue to be. It seems to stick to just about anything, although 3M says it’s for metals and plastics. I have used it for gluing D-rings – and other things – into my whitewater canoes.

The rings have been able to hold me boiling through big rapids, often upside-down. For this application the glue joint needs to be flexible and waterproof…and this stuff hasn’t ever failed me. How it is different from epoxy: Fills gaps. Flexes under stress without giving away. Sticks to smooth plastics like PVC or vinyl. Seems a LOT stronger than epoxies. You’ll have to find this in a specialty store or order it over the web. Shelf life is 1 year. — Fen Sartorius

Mixes up epoxy

I always used to buy epoxy locally in disposable dispensers that are supposed to dispense equal ratios of the components. The dispensers never work that well: one side always starts to move first and then to get a reasonably equal mix I have to mix up a lot more than I need.

The 3M duo-pack adhesives are sold separately from the dispenser. Because the dispenser is not disposable, it can be a decently built tool, like a caulk gun for epoxy.

The way it works is that you slip on the adhesive cartridge. The applicator has a plunger that pushes up the adhesive cartridge. Think caulk gun. The epoxy comes in double tubes like a doubled tube of caulk. When an adhesive has a different mixing ratio the tubes in the cartridge have different diameters. And there is a different plunger that fits in the tube. The supported mixing ratios are 1:1, 1:2 and 1:10 because those are the ratios of adhesives available. When you buy the system you get the first two plungers, but the 1:10 plunger is sold separately as it is used only for DP-8005 and DP-8010, I think. Just like a caulk gun you can, but you need not remove the adhesive cartridge between uses. The gun stays clean. There is no need to clean it. (Unlike a caulk gun, the adhesive doesn’t leak out the back and get on the gun.)

In fact, if you’re not so worried about waste there’s even a further convenience: static mixing nozzles. These nozzles attach to the end of the epoxy tube and do all the mixing for you so that it really works like a caulk gun: what comes out is ready to use, completely mixed epoxy.

But even if you don’t use the somewhat wasteful mixing nozzles you can still use the gun to extrude the correct ratio mix of 3M adhesive products and then hand mix. I have been able to mix up just the amount of epoxy I need when with the old system I would have mixed ten times what I needed. (No exaggeration here.)

I first got this system because I was trying to glue zinc-plated magnets to polyethylene. I tried regular epoxy. It doesn’t stick well to either one of these materials. There are two adhesives that I think are of particular note in the 3M lineup.

The DP-190 (which I have only used a tiny bit) is supposed to stick to everything except the “low surface energy” plastics. I saw that it is recommended for use with the zinc-plated rare earth magnets (by the magnet sellers). The DP-8005 is designed to stick to low surface energy plastics. I got it for my application.

I also got a small mat made out of teflon because nothing is supposed to stick to that. This was great for repairs using epoxy. I repaired something and laid it on the teflon and it peeled right off after it was cured.

According to 3M, epoxy shelf life is less than a couple years, so you don’t want to buy a lifetime supply at any given time. The shelf life of DP-8005 is only 6 months. The shelf life of the Scotch-Weld Two Part Urethane is 1 year. — Adrian M.

McMaster-Carr sells a very similar product much cheaper, half the cost, for $23. It does not use 3M cartridges. I have had good experiences with Lord adhesives that this gun does use. — KK

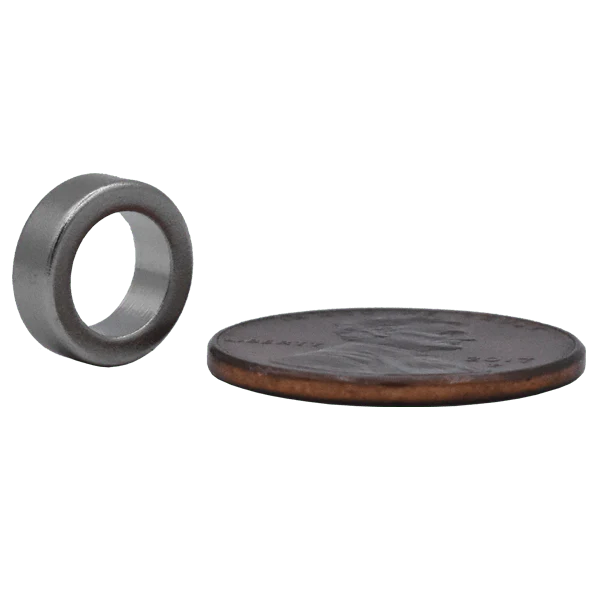

Best source for magnets

SuperMagnetMan, supermagnetman.net

I have been buying Neodymium Iron Boron (NIB) super magnets for years. Back then, Wondermagnets was the only source for hobbyists and they had quite a have changed. For the past five years, I have been ordering my magnets from “Mr. George the SuperMagnetMan,” unequivocally the best source today. His prices are the best on the net. His selection is vast: no one else has the stock he has or the variations in size of commonly available shapes. This is no exaggeration or hype. He’s got stuff you can’t get anywhere else and is constantly adding new items, like axially- and diametrically-magnetized NIB wedding rings and radially-magnetized ring magnets. He has magnets so large they are dangerous (fortunately he has put videos on YouTube that show you how to safely handle these monsters — with large leather welding gloves and a special wooden wedge and a 2×4!). He also sells magnetic hooks, pyramid shaped magnets, magnetic jewelry, teflon coated magnets, heart, star, and triangle magnets. You can even get powdered magnets that act like iron filings on steroids! You name it he’s got it. Most magnets are N45-N50 grade, the highest strength you can buy.

Some of the products I have ordered are the magnet powders, radially-magnetized ring magnet, various size sphere magnets, conical magnets, large rectangular magnets, cubes, and many others. Shipping charges are reasonable. Service is great. One time I ordered a bunch of stuff and never completely checked what I got. I went to use one of the magnets months later and found out it was the wrong size. He sent me the right size in the mail a few days after I emailed him.

Mr. George seems like a pretty cool dude, too. An electrical engineer, Mr. George develops magnet products himself and caters to other engineers, inventors, and hobbyists. He can have custom magnets made to order. He has also put up a series of educational videos on YouTube and has done a lot of work with kids. He has a saying, something like, “Give a kid a magnet and you have a friend for life.” — Laral

A strong hold on brake fluid

Like other adhesives, this one can be used on metals, glass, wood and leather, but it is the only household product I have ever used that will withstand constant exposure to gasoline and/or brake fluid. J-B-WELD will work in some cases, but you have to thoroughly clean and dry the surface or it will fail. Seal-All will seal a leak in a master cylinder-reservoir (non-pressure side) even if you apply it over brake fluid that has already wept out onto the surface. I have also used it to seal an old Coleman fuel tank, and also a weeping fuel fitting on the bottom of a gasoline tank on my bike. This stuff is not what I would consider a toolbox item, but I ride my bike far from home on occasion, and this is one of the items I like to keep in the “just-in-case” bag. — Jackie Gregory

Squeezes tubes dry

This Tube-Grip easily squeeze tubes of adhesive, calk, sealant, etc. with more precision, less waste with better finished results than other methods. Learning curve is short for starting and stopping applications. Tubes are squeezed beginning from the tube’s bottom seam, and 96% use of product efficiency is claimed. Very thrifty.

Mechanical advantage is claimed to be ten times more than by hand whether gripping vs. pinching. Less fatigue, more control. Concentration on product flow is enhanced because less physical effort is used during application. Tube squeezers for toothpaste and art paint are a different category. Some calling projects are too small for standard tubes of calk, or are in confined areas where a large gun won’t fit.

Tent seam sealing with drippy sealer is controlled better with whole arm movements and a hand grip vs. finger squeezing. I’ve used this 2” dispensing plier for at least 5-years and would not consider many squeeze tube projects without it. A 2 1/2” model also exists. — David McKenzie

Cool Tools